Adding a Subscription Delivery Program

Who is this for?

Read this if you are going to add a subscription offering for your product where there will be delivery at regular intervals. This play will coach you on how to save the maximum amount of money.

Summary

Some ecommerce businesses choose to sell their products through a subscription model, where a customer signs up to receive an order on a regular basis.

Subscriptions are great for Lifetime Value (LTV) creation and profitability, which is why more companies have looked into the idea. The secret is out that recurring revenue models are the fastest route to profitability.

The idea works better with some types of products more than others. Products that are more one-and-done, like appliances or electronics or high-priced items, aren’t a good fit. Other product types like consumables, replenishables, or regularly used items work very well. This is why ecommerce has exploded with vitamin, hygiene, food, and clothing businesses, among others, featuring a subscription model.

How subscription orders are managed is similar to single purchase orders for the most part, however, there are a few unique differences with fulfillment and delivery worth considering that can influence efficiency, cost, and customer experience.

This playbook will walk you through those considerations.

Overview

Subscription order delivery is a trade off between cost and precision.

On one end of the spectrum is optimizing for the cheapest possible delivery method. You know you have to ship something, so do it as cheaply as possible in order to improve margins, goes the thinking.

If this is your shipping policy for subscription fulfillment, don’t worry, you’re not alone in your desire to conserve costs.

On the other end is optimizing for precision. Customers hate to get a delivery on a date they didn’t expect, especially if it’s something that requires their presence for signature like a wine subscription service. Optimizing for precision typically results in a shipping policy like “We do 3-day for everything, so subscription orders go out 3 days before their delivery date.”

If this is your shipping policy with subscription fulfillment, don’t worry, you’re not alone in your desire to simplify operations.

Here’s the problem with either approach, however: You are almost always leaving money on the table or delivering packages to customers when they weren’t expecting it.

Finding the balance between the two so you can be both cost-effective and precise takes a considerable amount of technology than to simply optimize on one end of the spectrum or the other.

The Plays

The good news when setting up a subscription delivery program is that all the data needed to modernize the operation is present well ahead of time. We know—

- The customer destination address

- FC address(es) and inventory volumes per location

- Carrier methods available

- Box sizing requirements

What we don’t know is how to process that information in a way that informs the best pick-and-pack date for a given FC, the ideal carrier method to pick to secure the cheapest shipping rate, and the accuracy of delivering by a certain date.

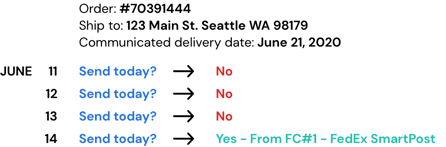

The variances of customer destination and carrier methods available make it so the decision is always dynamic to a single order, making any static policy (“Ship everything 3-day from this FC”) insufficient. The play instead requires daily real-time decisions.

Every day, per order, ingest all the given information for a subscription delivery date that is at least 15 days out. Fifteen is a magic number because every address in the country can hit within 15 days.

Look at available carrier shipping methods (USPS ReadyPost, FedEx 2-day, etc.) and determine the cheapest one available between an FC ZIP and the customer ZIP.

Check if inventory is available at the selected FC.

If all checks out, then see if that’s the right day to place a call with the FC. For example, if the cheapest method for a given order is 8 days, then you don’t need to worry about telling the FC to fulfill and ship the order until 8 days out; if you shipped it 15 days out, it’d get there 7 days too early.

Optimizing costs for subscription shipments is conceptually straight forward. You want to send the first package out as fast as possible as customers will be making a judgement decision on that experience. After a positive first experience, presumably the customer will continue to subscribe. In this scenario, it’s then easy to switch to the model discussed here where you pick the cheapest possible shipping method and send it out X number of days in advance.

That’s it. For this step, the process is very straight forward. The difficulty comes in the data analysis and algorithmic decision making which determines time and cost estimates, and then hooking that up with a fulfillment and warehouse network. It’s a fair bit of software that can take an engineering team a while to build.

Gotchas

The problem gets much more complex with each variable permutation among SKUs, boxes, carriers, and FCs.

First and foremost, it’s important that you communicate subscriptions in terms of delivery date, not ship date. If you don’t start with this the process of optimizing underlying delivery timing is broken from the outset.

If the timing of subscription deliveries is variable, for example, if the customer has a choice of replenishment every week, month, or two months, focus on whether 15 days is the right time to check all new scheduled orders.

If box sizing is variable, be sure that that is dynamically taken into account with carrier method selection.

If SKU counts can vary, like if sending a clothing subscription box with new products monthly, be sure that inventory management is integrated in real-time.

If your FC network has more than one FC, be sure that the right FC is selected up front, as inventory checking and carrier method selection is dependent upon that. To which, rebalancing between FCs is actually cheaper than you would think, and more likely than not another process you will want to add to the system.

Metrics

Since this is an exercise in balancing trade offs between cost and precision, you’ll want to track both.

- Are you continually picking the cheapest shipping method of available options? By logging all options at the time of selection, you can determine which percentage of the time you pick the cheapest. You want this to be close to 100%.

- Are you continually hitting exact delivery date projections? You’ll want to track when orders are delivered via carrier APIs, and log those results, which will give you the percentage of time in which you hit the estimated date. You want this to be close to 100%.

- Combined, how often does the cheapest shipping method hit the exact delivery date promise? You want this to be close to 100%.

Other metrics to consider:

- How long it takes to deliver customers on average.

- FC performance, which constitutes a lot of fulfillment specific metrics not discussed here. (See our blog post on FC analytics here.) Basically, ensuring that the upstream decision making fulfillment and shipment dates are correct, you need to make sure your FC/3PL partners are adhering to their SLAs. If they are constantly a day late, that could throw off precision performance.

How Shipium Does It

Shipium supports subscription order delivery management.

We connect with your 3PL/FC network, your store frontend, your order management system, and your carriers.

Then, we examine upcoming subscription orders and make a decision on when to push an order down to a given FC. The decision is custom software and algorithms built from our experience with Amazon Subscribe&Save.

Those orders are placed with the FC and shipped out accordingly. This hooks into your other processes like customer communications of an order being shipped with tracking information.