Pull vs. Push: How Amazon Revolutionized Its Supply Chain

Ecommerce operators have a bad habit of falling into "supply-side" thinking.

Forecasting demand has been figured out by someone else, they think, with merchandise ordered and ready to be placed into fulfillment centers.

Their job then becomes a linear planning exercise going from start to finish in increasingly smaller units. The merchandise goes from container to truck to pallet to box to door step.

This is push-based thinking. It's the idea that the job is efficiently and effectively pushing the flow of goods from beginning to end.

One of the most powerful ideas both Amazon and Zulily adopted was the idea of pull-based supply chain thinking.

Start from the end goal, and work backwards. Efficient and effective planning in reverse order is where actual stepwise optimizations can be found.

How Amazon did it

It's hard to blame operators for using supply-side thinking. After all, it's in the name—supply chain!

Demand-side thinking is superior to supply-side thinking, however, even for those whose role and responsibility is to manage the flow of said supply.

This is a wonky way of describing the famous, albeit unoriginal, Amazon principle "focus on the customer" which permeated everything the company did.

For operators, relentless customer focus meant reshaping metrics and planning to start from the customer and work backwards (demand) versus sourcing merchandise and work forwards (supply).

That's all high level talk, though. Let's walk through a real example.

Start with remembering the reason an ecommerce business exists.

It's to sell things to customers. That's it.

Securing customer transactions, and eventual loyalty, in a highly competitive world is the root reason for existence. Operations and ecommerce supply chains are an important (arguably the most important) part of the basic model. Operations exist to serve customers.

Consequently, the primary goal of operations is not for goods to flow as cheaply as possible through the e-commerce supply chain. I like to call that "bottomline" thinking—continuous cheapening of the supply chain purely for the sake of financial engineering.

Instead, the primary goal of operations is to help ensure customers buy from the company's channel, then follow through on delivering the brand promise.

Amazon understood consumers wanted things to be fast, free, and convenient. More consumers would buy with us versus someone else if we met those demands. Yet, profitably fulfilling orders that delivered on those demands wasn't marketing's responsibility, it was on the operations team.

So we worked backwards.

We started by forecasting what customers want and where they were located. If we could get smarter at projecting the probabilistic locations of customers for SKUs or categories, we could ensure delivery to those customers would be fast and free.

Now that we understood what our customers wanted, we worked backwards from there. The last mile is the first place that touches the customer. All aspects of last mile fulfillment were optimized, including which carrier, which method, and which route would give the fastest delivery at the lowest cost.

The next logical step back in the chain was how to proactively plan the fulfillment of orders through the fulfillment network. Inventory positions and demand were constantly changing. It was imperative we built a fulfillment planner that simultaneously accounted for supply, demand, labor and even proactively transferring inventory between FCs. The innovation was to consider all of these factors on behalf of the customer because we knew that we were doing everything possible to keep our promise.

With intelligent routing and re-allocation in place, we then worked backwards to understand how to procure inventory. We automated every step in the procurement chain including how much to buy, where to place it and how often to reorder. These decisions ensured that we we got inventory close as possible to the customer and that we did it the most cost-effective way.

Think of each "decision point" an operator has to decide, going in reverse order from customer demand, and optimize that way.

Asking the right questions

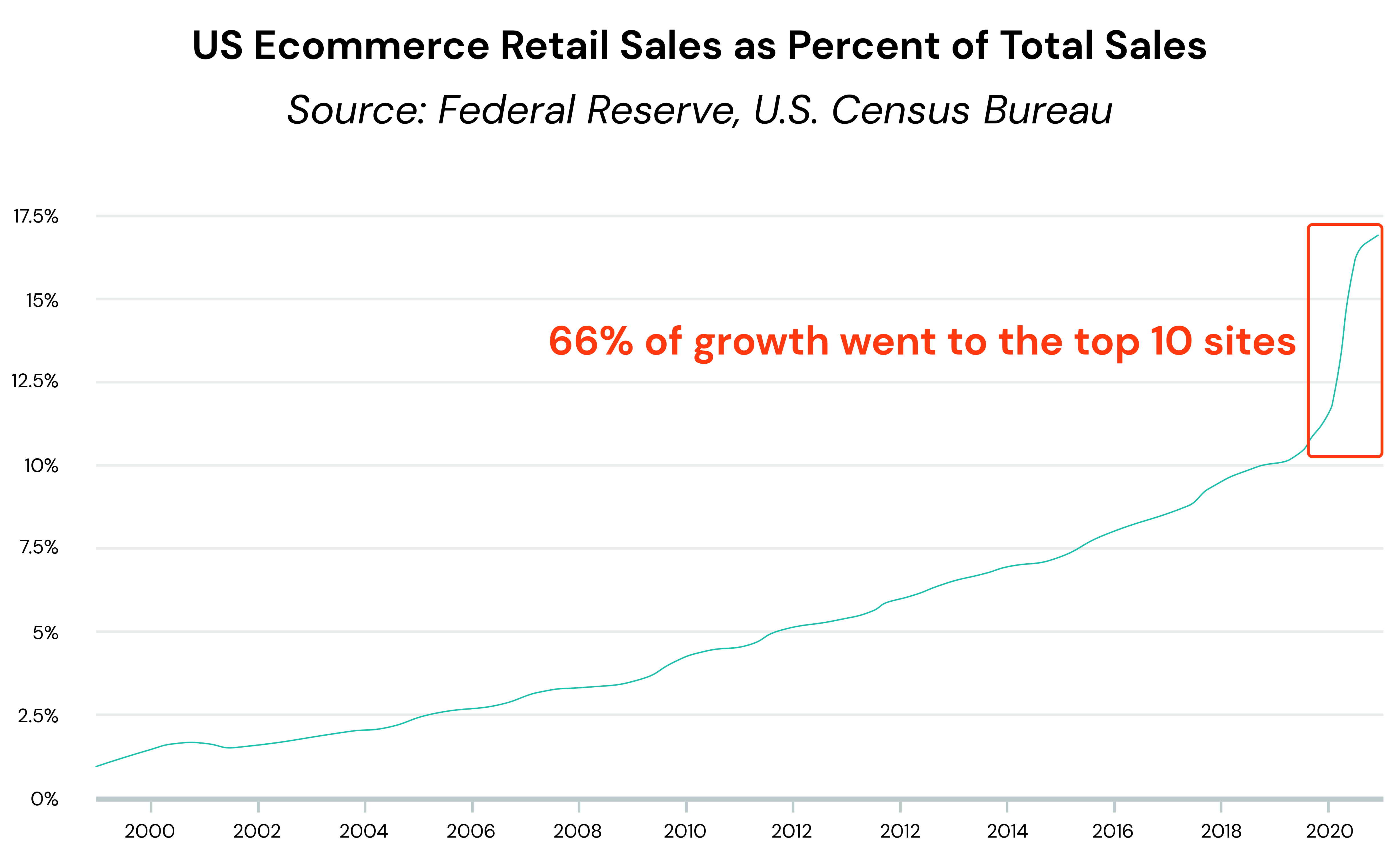

The switch in thinking made all the difference in Amazon’s successful scaling. Other top ecommerce destinations have made similar switches, and the proof is in the pudding.

The majority of ecommerce’s explosive growth during the pandemic have gone to the top ecommerce sites. More customers shopping online, pandemic or otherwise, just means there are more people who want things free, fast, and conveniently. Heavy operational investments in providing those attributes by the likes of Walmart, Target, Home Depot, and Best Buy are partly why these companies are capturing most of the growth and profits.

Other companies use push thinking to create a weekly/monthly/quarterly plan, allocate inventory accordingly, and attempt continuous management (e.g. replenishment) through updating the plan. When a plan is off, more merchandise is "pushed" through to accommodate.

While there is some demand thinking involved (original forecasting), it's still oriented from the point of view I have this amount of merchandise, where should I put it?

The winners, including the top sites, are simply switching the question to this: I have these customers. How much inventory should go in each FC to meet their demand?

Changing an orientation to the end of the supply chain and working backwards is the kind of organizational shift that will both help the topline of increasing revenue and loyalty, but also the bottomline but ensuring the most expensive operating expenses (shipping) are as optimized as possible.

Jason is co-founder and CEO of Shipium where he guides the company's vision towards becoming the world’s best supply chain technology platform for ecommerce and retail. Prior to founding Shipium, he spent 19 years at Amazon as VP of Retail Systems and VP of Forecasting & Supply Chain. While there he owned the global software and operations group that powered Prime, Subscribe & Save and Pricing. He is a University of Washington grad and an engineer at heart who loves solving complex scaling problems.