Use Shipium’s Volume Balancing to Meet Carrier Commitments at the Lowest Cost

Meeting your shipping carrier volume commitments is a critical part of managing outbound fulfillment. But many shippers are stuck using outdated manual methods that are time-consuming and often leave cost savings on the table.

This is a familiar challenge for many large-scale shippers. They have to meet specific volume thresholds with carriers like FedEx or UPS to unlock discounted rates, but their current systems assign carriers based on static criteria — for example, assigning carriers to specific ZIP codes based on historical performance data. This approach is rigid, and can often lead to overutilizing one carrier at the expense of others, limiting opportunities for cost reduction and performance optimization.

In this blog, we’ll explore how operators can leverage Shipium to balance volume commitments with other business priorities like cost reduction and improved on-time performance.

The Problem With Manual, Static Volume Allocation

Traditional approaches for meeting volume thresholds create the following challenges.

Inability to Respond to Real-Time Changes

Legacy systems necessitate static processes, which are fundamentally unable to adapt to changing circumstances that impact fulfillment operations. Examples include:

- Sudden volume spikes: During peak seasons or promotional events, a system configured with static rules can’t automatically shift volume to a carrier with available capacity. This can lead to bottlenecks and missed service level agreements (SLAs).

- Carrier performance issues: If a carrier experiences a service disruption — due to weather, a strike, or network congestion — a static process may continue to tender shipments to them, even if a competitor has a clear advantage in cost and speed at that moment.

- Capacity shortages: A manual system can't see which carriers have excess capacity at a specific moment. It continues to assign shipments based on predetermined rules, missing opportunities to offload volume to a carrier who can handle it more efficiently.

Suboptimal Cost Management

Static rules often prioritize a single factor, like a pre-negotiated discount, at the expense of overall cost optimization. This can lead to:

- Missed rate shopping opportunities: By locking in a carrier based on a static rule, you lose the ability to rate shop for every individual shipment. This prevents you from taking advantage of lower spot rates or a different carrier's lower cost for a specific package profile.

- Hidden costs: Manual processes are more error-prone, which can result in unexpected fees. For example, a data entry mistake on a package's dimensions or weight can lead to costly carrier adjustments on an invoice.

- Poor negotiation leverage: Without real-time data on carrier performance and rates, shippers lack the visibility to prove which carriers are performing well and which aren't, limiting their leverage during contract negotiations.

Increased Manual Effort and Human Error

The manual nature of these systems is a drain on resources and a source of risk.

- Labor-intensive monitoring: Logistics teams must spend hours each day manually tracking carrier performance and adjusting routing rules in spreadsheets or legacy systems to stay on top of volume commitments.

- Human error: Data entry mistakes, miscalculations, and incorrect rule adjustments are common, leading to incorrect carrier assignments, delayed shipments, and customer dissatisfaction.

- Scalability issues: As volume grows, manual processes often become unmanageable. Adding more staff to a flawed process only increases complexity and cost without fundamentally solving the root problem.

A Smarter Approach: Dynamic Volume Allocation

One of Shipium’s core use cases is helping shippers to optimize their strategies for volume balancing. Let’s explore how.

The Power of Predictive Analytics

Shipium doesn't just react to what has already happened; the platform proactively plans for what’s to come using:

- Volume Projection: Our models analyze historical shipping data — considering factors like day of the week, seasonality, and promotional events — to forecast the total volume of shipments expected for the day. This provides a clear target for each carrier's required volume commitment.

- Hourly Distribution Monitoring: The system monitors the actual volume being tendered to each carrier on an hourly basis.

These predictive and monitoring capabilities give the system a comprehensive view, allowing it to act as a co-pilot for your logistics team, not just a set of rigid rules.

Dynamic Adjustments

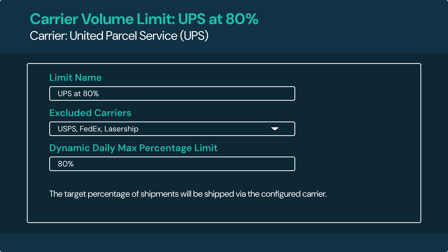

Based on the volume projections and real-time monitoring detailed above, Shipium applies dynamic "modifiers" to the rating engine. This is how it influences carrier selection without manually gating or blocking them.

Here's a deeper look at the process:

- Cost Modification: If the system predicts that you are overcommitting to a specific carrier, it will automatically increase the effective "cost" of that carrier in the rate shopping model. For example, if your commitment is 70% with Carrier A, but your hourly volume is tracking at 73%, the system might add a nominal surcharge to Carrier A's rate for the next hour. This doesn’t change the carrier's contract price, but it makes them less competitive in the rate shopping model for the next shipment, nudging the system to select another, now more cost-effective carrier.

- Business Rule Optimization: This process ensures that shipments are still being routed in a way that meets your business objectives. For example, a shipment with an urgent delivery date will still be routed to the carrier who can meet that date, even if the system has added a cost modifier to that carrier to manage volume. The dynamic modifier works within the bounds of your core business rules (ex. service level agreements, transit time, etc.)

- The “Right” Shipments, Not the “First” Shipments: This dynamic process solves a fundamental flaw of static systems. A traditional system might send the first 70% of packages to a specific carrier, regardless of how cost-effective individual shipments are. A dynamic system sends the "right" 70% — the shipments that are most cost-effective to send via that carrier — while routing the remaining shipments to the best option available.

Continuous Learning and Improvement

The process doesn’t stop at real-time adjustments. The data collected from shipment confirmations feeds back into the model, creating a continuous loop of learning and improvement. Our models assess which adjustments were most effective, improving projections and decision-making over time.

Wrapping Up

By leveraging predictive analytics, dynamic modifiers, and a continuous feedback loop, Shipium provides a level of control and optimization that is impossible to achieve with manual, static methods for volume balancing. In doing so, we ensure that you not only meet your contractual commitments, but do so in the most cost-effective way.

If improving your volume balancing strategy is a priority, reach out to our team here to see how we can help.